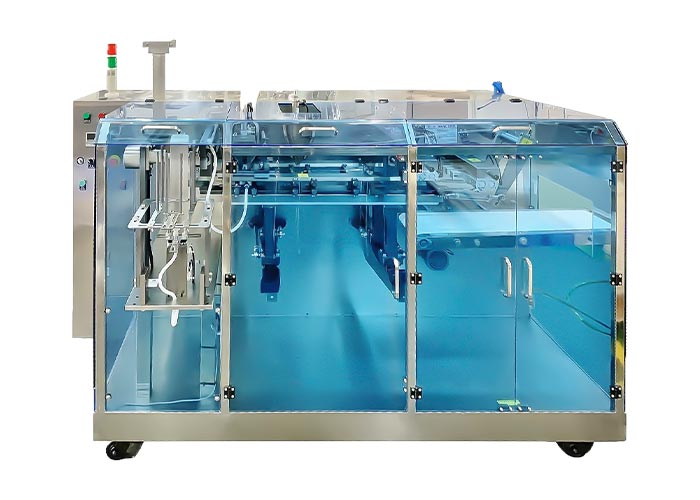

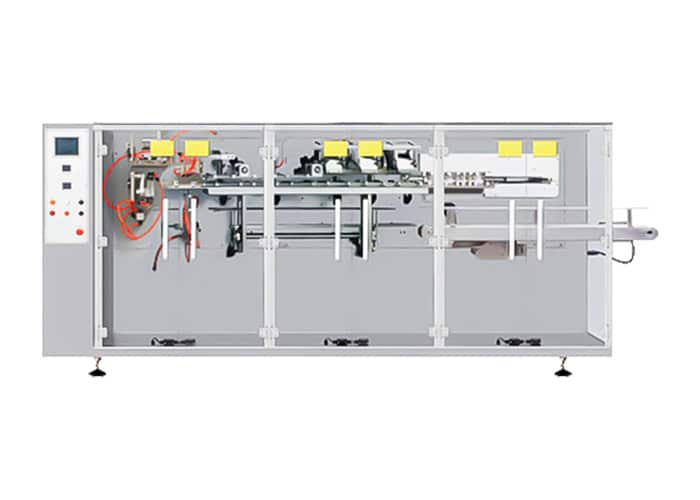

LMRH Rotary Premade Doypack Pouch Packaging Machines

The LMRH Series GMP Compliant High-Performance Rotary Premade Pouch Packaging Machines fill and seal pouches in one automatic process. These rotary pouch packaging machines are high-speed machines and suitable for powder, grains, liquids, and parts for food and other industries. Rotary machines are compact machines and have a space-saving design.

The LMRH Rotary Pouch Packaging Machines have some distinctive and advanced optional features that make them stand out from the crowd. An advanced auto lubrication system ensures longer virtually maintenance-free life of the machine for a long time. The temperature control of the sealing heaters of these machines is in the HMI touch screen which streamlines the control panel and offers easier access and intuitive control of the sealing temperatures from the HMI touch screen display. The temperature controllers are a part of the PLC in these machines which makes the control system more robust. Last but not the least, these machines support remote diagnostics and troubleshooting capability over a wired or wireless network from the manufacturer.

LENIS provide GMP Documentation Package (IQ/OQ/PQ) as an option for all the supplied equipment.

LENIS also provides NRTL based machine certification option for US customers and mandatory machine certification in accordance with CSA directives for Canadian customers. Most of our machines come with CE certification as a standard.

Bag Types

These machines can work with pre-made bags of the following types:

- Stand-up pouches or Doypack pouches with or without zippers

- Spout pouches for liquid packing

- 3-side sealed pouches with or without zippers

- 4-side sealed pouches with or without zippers

Filler Options

- Auger Filler (for powder products)

- Volumetric Cup Filler (for grains)

- Multi-head Weigher (for grains and granular items like chips, candies, etc.)

- Piston Pump (for liquid products)

- Tablet Counting Filler (for tablets)

- Vibrating Fillers (for block items, nails, screws, etc.)

Machine Options

- Hole punch device

- Gas flush device

- Middle capping device

- Zipper opening device

- Vertical bag loading system

- Horizontal bag loading system

- Inline check weigher

- Dimple plated contact parts for sticky products

- Teflon plated contact parts for highly sticky products

- Metal detector at the output

- Date code printer, etc. are among many options available

Build Material Options

- SS304 stainless steel based product contact parts for general food/cosmetics/pharmaceutical industries

- SS316 corrosion-resistant stainless steel-based product contact parts for highly corrosive products like salt, chemicals, etc.

Optional & Related Equipment

- Raw Material Handling Equipment: Belt Conveyors, Bag Splitting Machines, Large Bag Splitting machine directly from pallets

- Industrial Powder and Grain Mixers: Ribbon Mixers, Paddle Mixers, Plow Mixers & Open Type Mixers

- Powder & Screw Conveying Equipment: Screw Conveyor, Belt Conveyor, Bucket Conveyor, etc.

- Cartoning & Boxing Machines

- Box Shrink Wrapping Machines

- Palletizing Robots: Cartesian Robots, Six-Axis Robots

- In-line Pallet Stretch Wrapping and Labeling Machine

- Possibility of machine integration with ERP system. (SAP, Microsoft Dynamics, and other ERP software)

- SCADA integration

- Agitator/mixer for liquid or paste products

- Product counter and stacking belt conveyor

- Rotary table for the convenient collection of the finished products

- Extra filler equipment for different powder, granular, liquid, or part type products packaging in a single machine. The choices are: volumetric cup filler, 2-head/4-head linear weigher, piston pump filler, auger filler, tablet counting filler, and vibrating filler

- Air compressor

Standards

- In accordance with CE Standards

- Optional accordance with OSHA accredited NRTL Certification for USA and CSA for Canada

LENIS Rotary Pre-made Doypack/Flatpack Pouch Packing Machine

LENIS Rotary Pre-made Flat-bottom Standup Pouch Packing Machine

LENIS Rotary Pre-made Doypack Standup Pouch Packing Machine