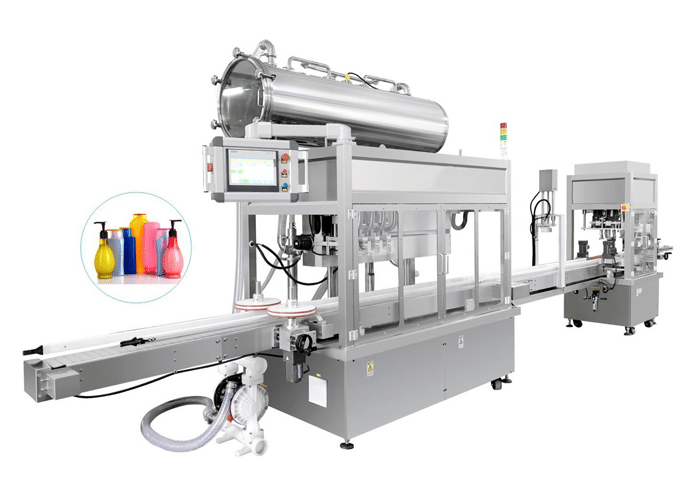

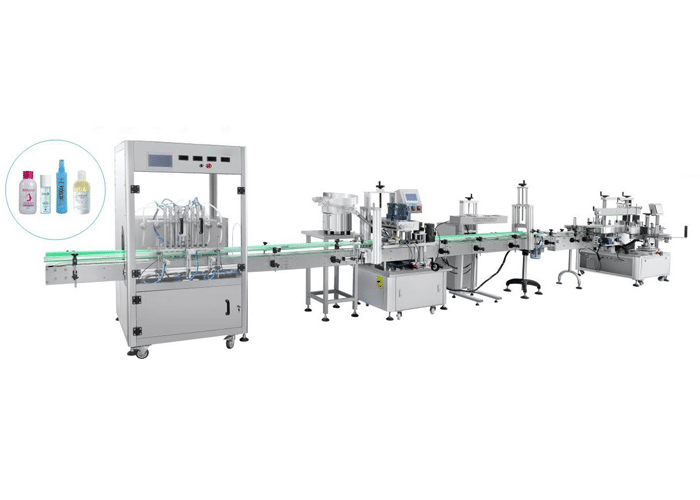

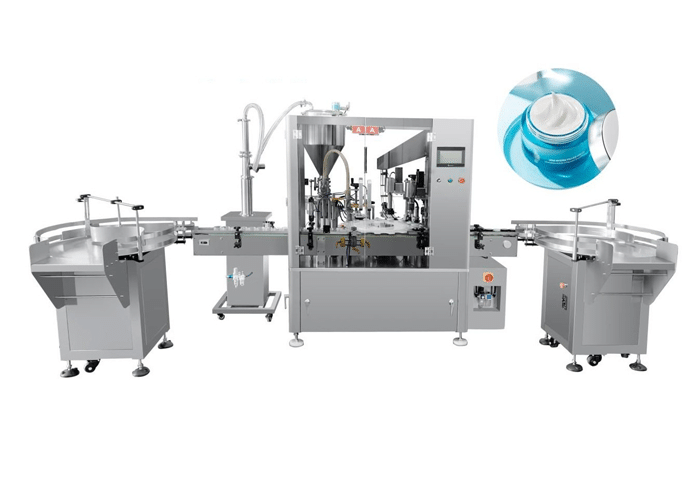

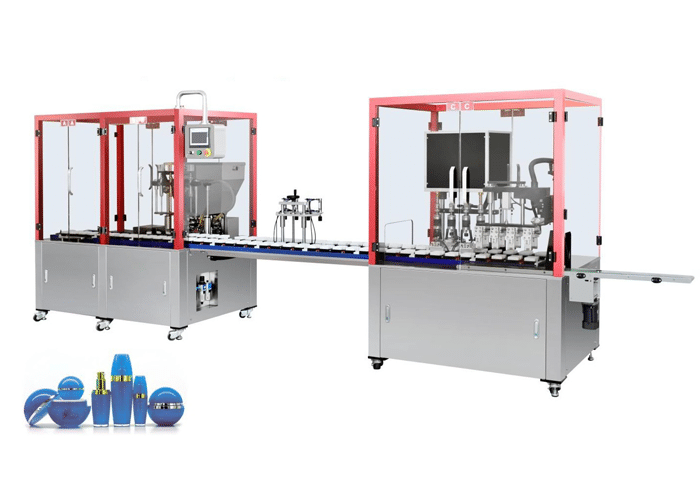

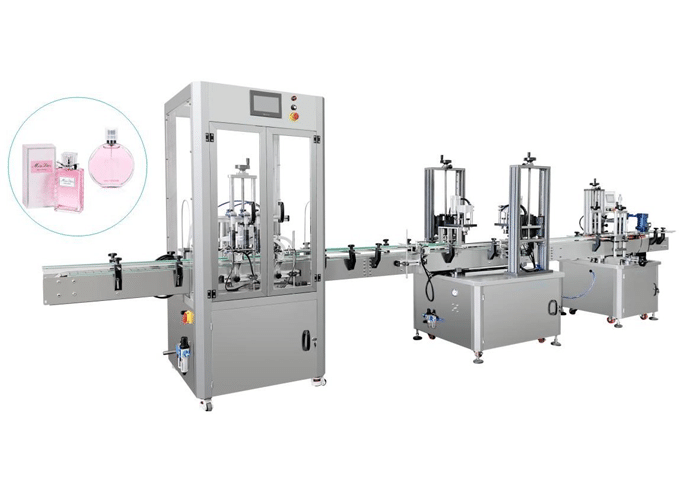

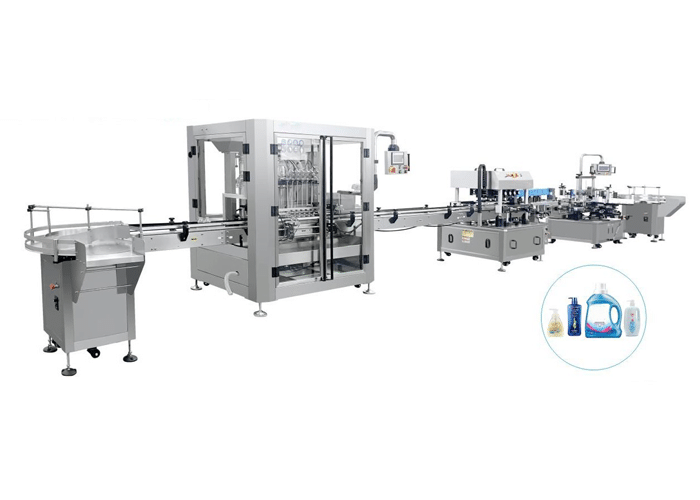

LiquiPACKER-SP Automatic Filling, Capping & Labeling Line for High Viscosity Liquids, Pastes & Creams

Description

Features

Specifications

Videos

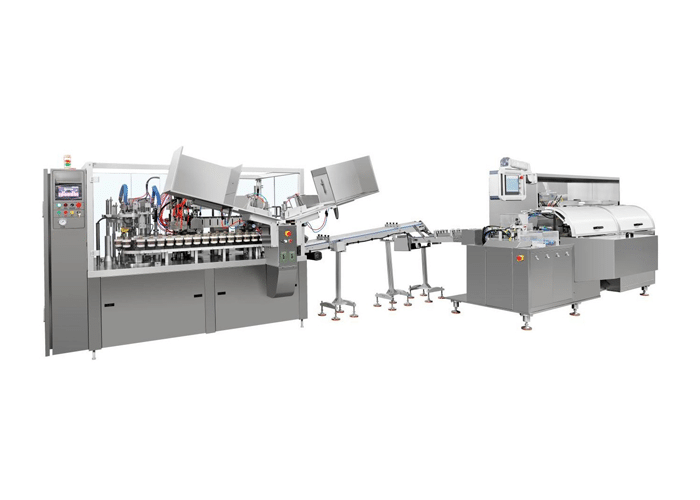

The LiquiPACKER-SP is an automatic servo-piston filler based bottle filling, capping and labeling line for high-viscosity liquids, pastes & cleams. This automatic bottle packing line is widely used in cosmetics, food, pharmaceutical and chemical industries.

Features

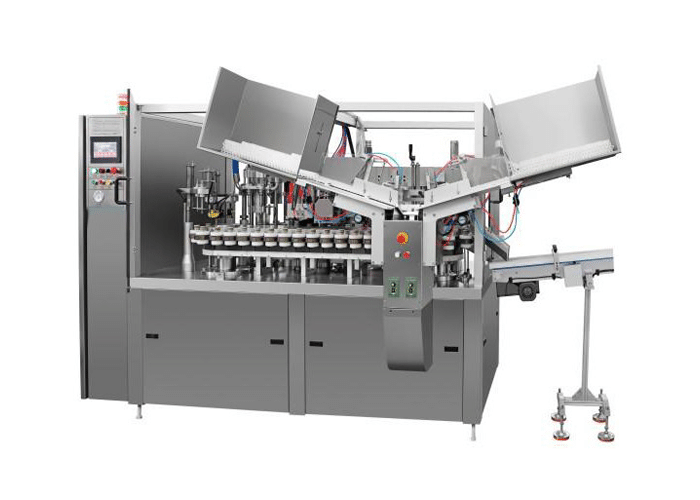

- Suitable for high-viscosity liquids, pastes & creams using servo-piston pump based fillers.

- Standard 4-6-8 head filling machine. Also, can have customized number of filling heads.

- Automatic bottle detection system ensures no filling on no bottle detection. This helps cleanup of unwanted mess of liquids.

- Servo-piston pump based product filling.

- Pneumatic cylinder or servo motor based drive nozzles.

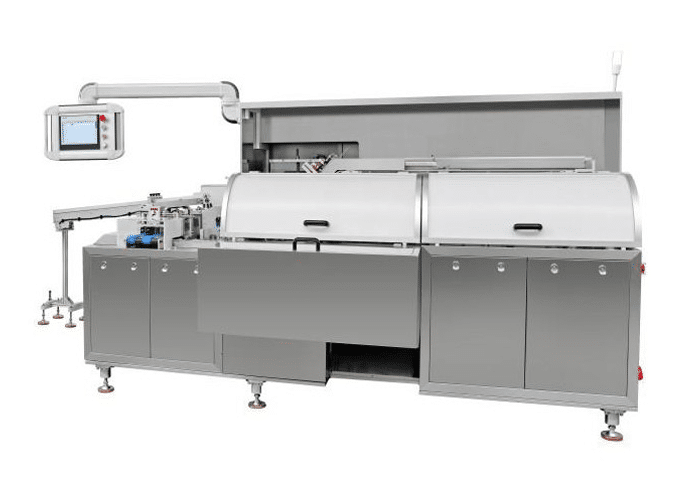

- Filling/Capping/Labelling speed is 30~40 bpm.

- PLC based robust control system with Touchscreen based HMI for machine control

Standards

- In accordance with CE Standards

- Optional accordance with OSHA accredited NRTL Certification for USA and CSA for Canada