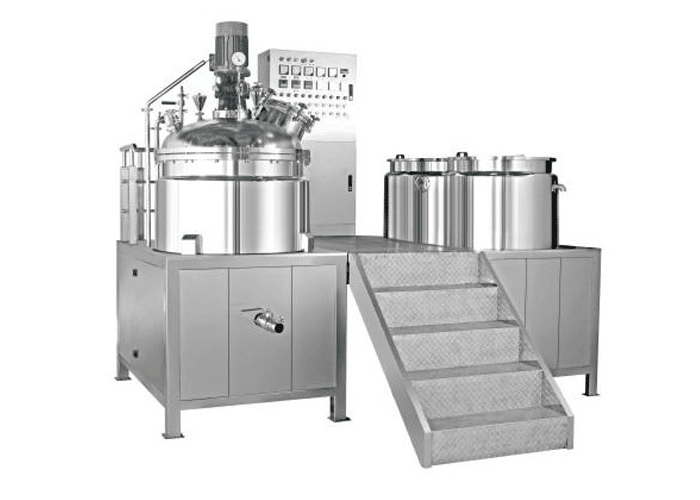

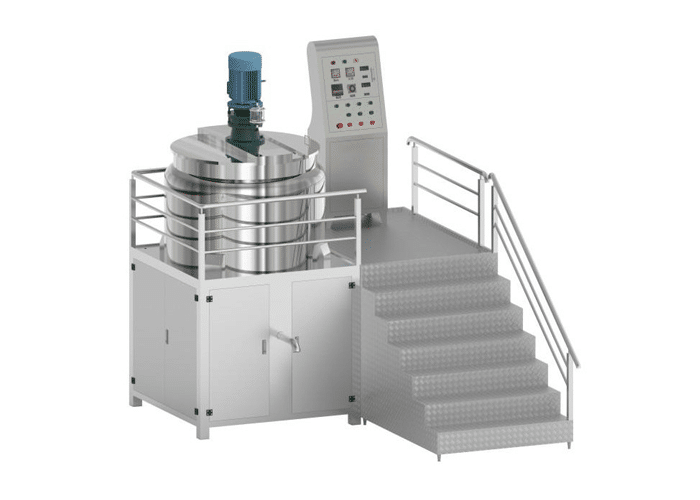

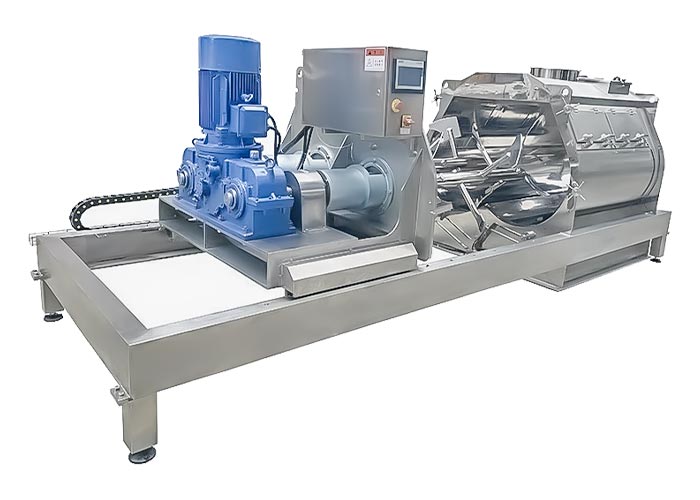

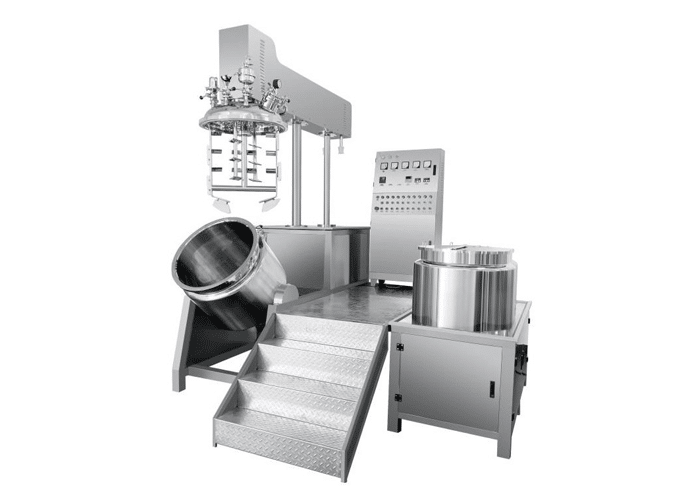

VACUMIX-HL Vacuum Emulsifying Mixers – Hydraulic Lifting Type

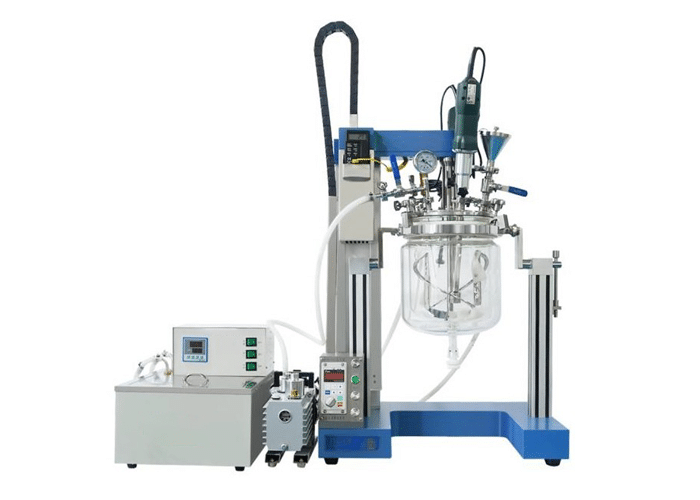

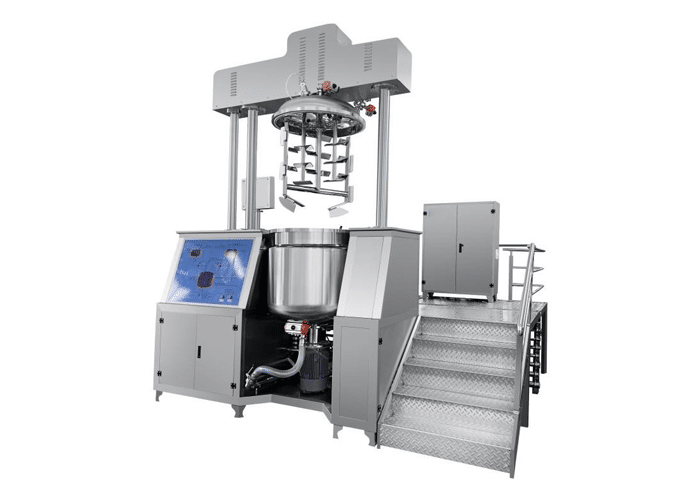

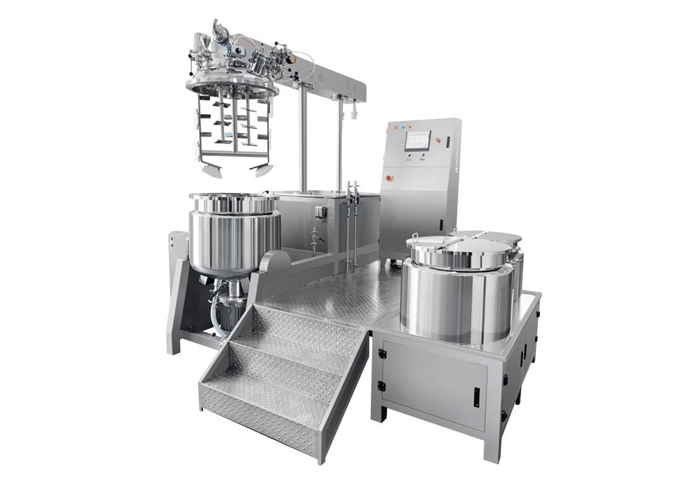

The VACUMIX-HL series vacuum emulsifying mixers are mainly composed of water pot, oil pot, emulsifying pot, vacuum system, heating and cooling system, lifting system (optional), electric control system (PLC is optional), operation platform and stairs, etc.

Automatic vacuum emulsifying mixers adopts PLC control system where all the function parameters can be adjusted through intuitive touch screen HMI. Automatic pneumatic valves control for the pipes and fittings. The water/oil pot have automatic suction mechanism to the main pot. Also, automatic discharge of finished products from the main pot. Intelligent recipe system can save various parameters and functions during production for different products, and can be directly called for the next batch of production. Ensures ease of operation and an efficient production system.

Features

- Working capacity from 10L to 5000L with different models.

- Suitable for cream and emulsion of 10 ~ 300,000 cps viscosity.

- Complete process of mixing, dispersing, homogenizing, vacuum, heating and cooling in one unit.

- German technology based homogeneous machine with high quality double-sided mechanical seal ensures perfect particle size of 2 micrometers.

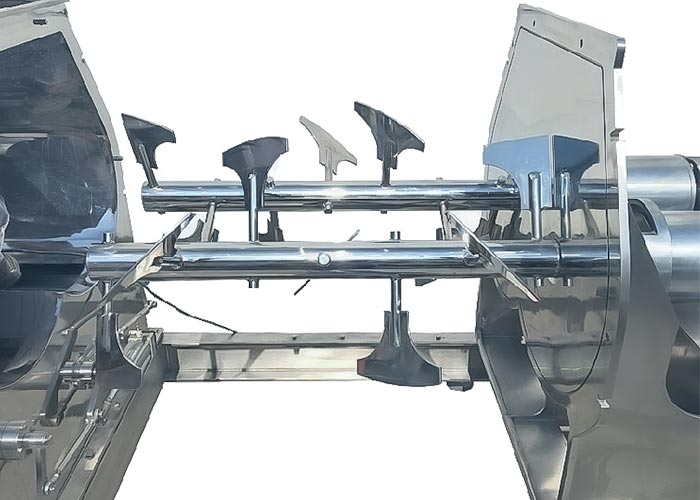

- Variable speed control for homogenizer and agitators.

- Ultimate vacuum -0.08 MPa.

- Vacuum suction system to take out the bubbles during mixing and transfer of the ingredients.

- The main mixer adopts single/dual oil-hydraulic lifting system for easy cleaning and maintenance, and tilting system for discharging finished product.

- Tilting discharge, pump discharge or compressed air to discharge the finished products.

- Spray ball is equipped to connect customer’s CIP system. We also provide our own CIP system.

- All contact parts are made of SUS 316L. All tanks and pipes adopt mirror/matt polishing and conform to GMP standard.

- Different jacket designs are available for steam or electric heating with temperature control module.

Standards

- In accordance with CE Standards

- Optional accordance with OSHA accredited NRTL Certification for USA and CSA for Canada