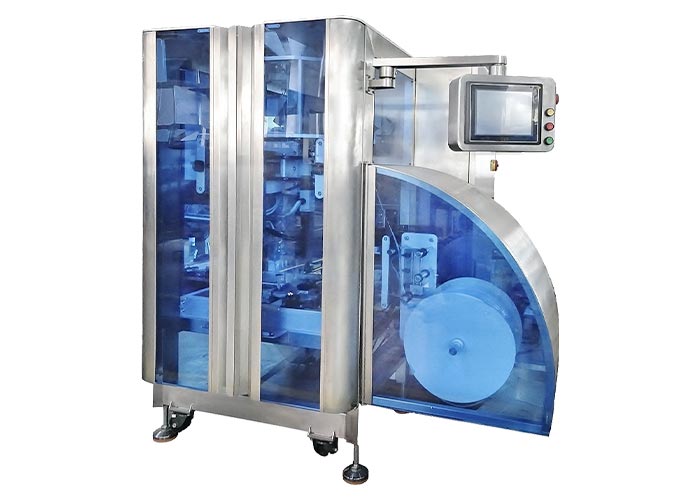

LMUHP-5S High Speed Continuous Motion Vertical Form, Fill & Seal (VFFS) Pouch Packaging Machines

The LMUHP-5S High-Speed Continuous Motion Vertical Form, Fill & Seal (VFFS) Pouch Packaging Machines are high speed, continuous type VFFS machines with five servo motors and specifically designed for the wrapping of a wide range of product types in medium to small-sized bags and capable of packing up to 150 bags per minute maximum. These machines focus on markets where the main requirements are economy of packaging, higher productivity at a lower cost, ruggedness, and reliability due to the simplicity of design, and ease of operation of the machines. The automated working cycle includes bag forming, filling, and sealing of the bag. The machine uses packaging film material from a single roll. These machines continuously feed the film over the bag former and ensured a high speed of operation. The cycle is managed and controlled by a programmable logic controller and a touch screen HMI for easier operation and recipe management.

Supported Bag Types

- Pillow bags

- Gusset bags of blocked bottom bags

- Seal type bags

Filler Options

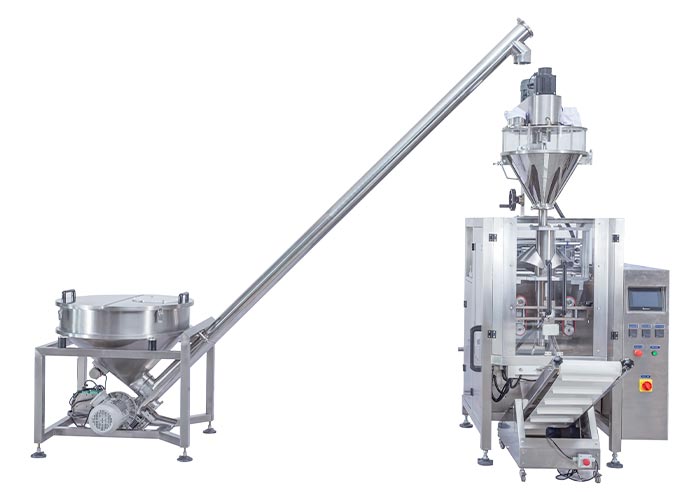

- Auger Filler (for powder products)

- Volumetric Cup Filler (for grains)

- Multi-head Weigher (for grains and granular items like chips, candies, etc.)

- Piston Pump (for liquid products)

- Tablet Counting Filler (for tablets)

- Vibrating Fillers (for block items, nails, screws, etc.)

Machine Options

- Gusset device

- Hole punching device

- Inflating device

- Special PE film sealing heaters

- Anti-static device

- Horizontal seal cooling

- Nitrogen filling device

- Vibrating device

- Sealing device

- Easy tear device

- Bag support device

- Evacuating device

- Automatic film align the system

- Horizontal sealing servo drive system for higher speed

Build Material Options

- SS304 product contact parts for general food/cosmetics/pharmaceutical industries

- SS316 product contact parts for highly corrosive products like salt, chemicals, etc.

Optional Equipment

- Raw Material Handling Equipment: Belt Conveyors, Bag Splitting Machines, Large Bag Splitting machine directly from pallets.

- Industrial Powder and Grain Mixers: Ribbon Mixers, Paddle Mixers, Plow Mixers & Open Type Mixers.

- Powder & Grain Conveying Equipment: Screw Conveyor, Belt Conveyor, Bucket Conveyor, etc.

- Cartoning & Boxing Machines

- Box Shrink Wrapping Machines

- Palletizing Robots: Cartesian Robots, Six-Axis Robots.

- In-line Pallet Stretch Wrapping and Labeling Machine

- Agitator/mixer for liquid or paste products

- Product counter and stacking belt conveyor

- Rotary table for the convenient collection of the finished products

- Extra filler equipment for different powder, granular, liquid or part type products packaging in a single machine. The choices are: volumetric cup filler, 2-head/4-head linear weigher, piston pump filler, auger filler, tablet counting filler, and Vibrating filler

- Air compressor

- Possibility of machine integration with ERP system. (SAP, Microsoft Dynamics, and other ERP software)

- SCADA integration

Standards

- In accordance with CE Standards

- Optional accordance with OSHA accredited NRTL Certification for USA and CSA for Canada

| Parameters | Specifications |

|---|---|

| Maximum Capacity | 120 bags/minute |

| Bag Width | 90 ~ 200 mm |

| Bag Length | 50 ~ 300 mm |

| Bag Type | Pillow bag (Optional: gusseted bag, strip bag, bags with euroslot) |

| Max Filling Volume | 2.4L |

| Film Width | 120 ~ 420mm |

| Film Thickness | 0.04 ~ 0.09mm |

| Air Cconsumption | 0.8MPa, 0.3m3/min |

| Power & Supply Voltage | 5.6 kW, 220/380V, 50/60Hz |

| Dimensions (L x W x H) | 1900mm x 1180mm x 1550mm |

| Machine Weight | 700kg |