LMSTS-500 Single-Lane Shaped Stickpack or Sachet Packaging Machines

The LMSTS-500 is a pneumatic drive based VFFS single-lane shaped sachet packing machine that forms, fills, and seals pouches and sachets in one automatic process. This machine creates attractive mold cut shape according to customer’s requirement that are not a simple square.

Three models of these machines are commonly used for liquids and pasty products but are also suitable for powders, grains or granular products.

The LMSTS-500 series has three models of machines. The G model is for grains, granular products, and free-flowing powder packing and comes with a Volumetric Cup Filler. The P model of this machine is for non-free-flowing powders and also can be customized for free-flowing micro-grains and free-flowing powders and comes with an Auger Filler. The L model, which is the most common for this model of this machine is for liquid or pasty product packing and comes with a Piston Pump Filler. We can freely discuss your need for further customization of this machine to achieve your production goal. A small but rugged industrial machine for small production facilities with a variety of products and ideal for startups launching and testing a new product.

Customization options (not limited to):

- Sachet shape

- Videojet inkjet printer integration

- Domino inkjet printer integration

- High density and high quality code printing using Domino thermal inkjet printers (pharmaceutical use)

- Code verification vision system integration (pharmaceutical use)

Bag Types

This single-lane machine can be customized to produce different shaped sachets. It has three models for non-free-flowing powders, free-flowing powders or granulates and liquid or pasty products.

Filler Options

- Auger Filler (for powder products)

- Volumetric Cup Filler (for grains)

- Piston Pump Filler (for liquid and pasty products)

Optional Equipment

- Screw elevator/conveyor for automatic continuous feeding of powder products

- Z-bucket elevator for automatic continuous feeding of granular products

- Agitator/mixer for liquid or paste products

- Product counter and stacking belt conveyor

- Extra filler equipment for different powder, granular, liquid, or part type products packaging in a single machine. The choices are: volumetric cup filler, multi-head weigher, piston pump filler, auger filler, tablet counting filler, and vibrating filler

- Air compressor

- Possibility of machine integration with ERP system. (SAP, Microsoft Dynamics, and other ERP software)

- SCADA integration

- Complete production line including Metal Detector, Boxing Machines, Wrapping Machines, etc.

Detailed Operations Manual in English

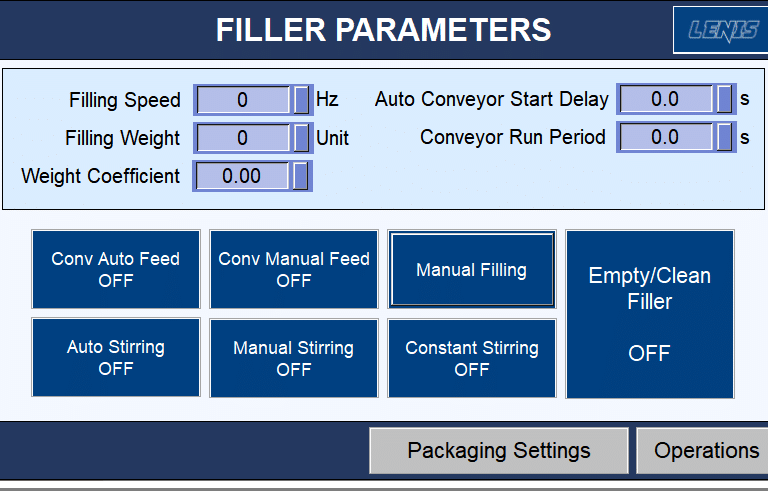

LENIS has prepared a very detailed Operations Manual in English for North American and international clients to make installation, commissioning, and troubleshooting the machine a breeze. Every item on the UI pages are described in details and detailed operational and troubleshooting instruction has been added in the manual to make it very easy to maintain the machine. A step-by-step short form machine running manual is also included for beginners in the packaging world.

Standards

- In accordance with CE Standards

- Optional accordance with OSHA accredited NRTL Certification for USA and CSA for Canada

| Parameters | LMSTS-500P | LMSTS-500G | LMSTS-500L |

|---|---|---|---|

| Material | Body: SS304 (Stainless Steel), SS316 Option | Body: SS304 (Stainless Steel), SS316 Option | Body: SS304 (Stainless Steel), SS316 Option |

| Measuring Technology | Auger Filler for Powder Packing | Volumetric Cup Filler for Granular Item Packing | Piston Pump Filler for Liquid Packing |

| Controller Technology | Programmable Logic Controller (PLC) & HMI Touch Screen | Programmable Logic Controller (PLC) & HMI Touch Screen | Programmable Logic Controller (PLC) & HMI Touch Screen |

| Bag Type | Irregular shaped sachet | Irregular shaped sachet | Irregular shaped sachet |

| Filling Range | 0 ~ 50 mL | 0 ~ 50 mL | 0 ~ 50 mL |

| Film Width | 60mm ~ 220mm | 60mm ~ 220mm | 60mm ~ 220mm |

| Bag Width | 30 ~ 110 mm (One size within this range to be fixed) | 30 ~ 110 mm (One size within this range to be fixed) | 30 ~ 110 mm (One size within this range to be fixed) |

| Bag Length (Standard) | 50 ~ 165 mm | 50 ~ 165 mm | 50 ~ 165 mm |

| Bag Length (Customized) | 50 ~ 204 mm | 50 ~ 204 mm | 50 ~ 204 mm |

| Packaging Film | Laminated Film, OPP/CPP, OPP/CE, PET/PE, NILO/PE, PE | Laminated Film, OPP/CPP, OPP/CE, PET/PE, NILO/PE, PE | Laminated Film, OPP/CPP, OPP/CE, PET/PE, NILO/PE, PE |

| Packing Speed | 20 ~ 40 bags/min | 20 ~ 40 bags/min | 20 ~ 40 bags/min |

| Filling Accuracy (Error) | ±1 ~ ±6% Depending on Packet Size | ±1 ~ ±3% Depending on Packet Size | ±1 ~ ±3% Depending on Packet Size |

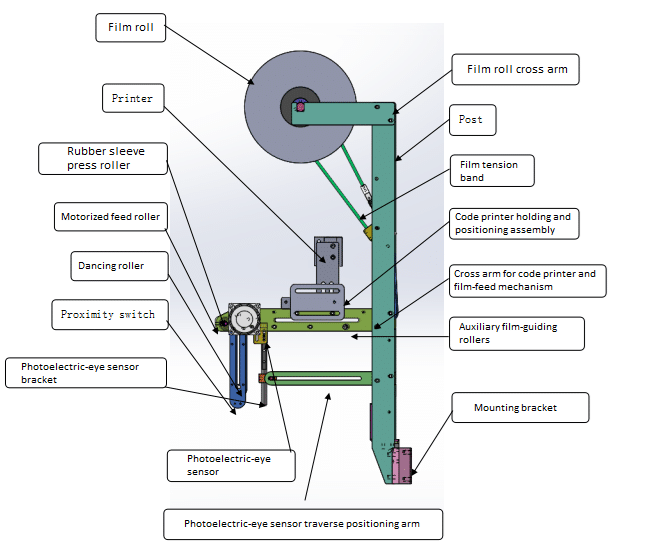

| Additional Feature 1 | Photoelectric Eye Sensor (included) | Photoelectric Eye Sensor (included) | Photoelectric Eye Sensor (included) |

| Additional Feature 2 | Date Code Thermal Printer (included) | Date Code Thermal Printer (included) | Date Code Thermal Printer (included) |

| Power & Supply Voltage | 1.5 kW, 220V, 1Ø, 50/60Hz | 1.5 kW, 220V, 1Ø, 50/60Hz | 1.5 kW, 220V, 1Ø, 50/60Hz |

| Crate Dimensions (L x W x H) | 1100mm x 1000mm x 2000mm | 1100mm x 1000mm x 2000mm | 1100mm x 1000mm x 2000mm |

| Gross Weight | 300kg | 300kg | 300kg |

| Net Weight | 250kg | 250kg | 250kg |

Single-Lane Shaped Sachet Packing Machine Video

LMSTS-500 can be customized for liquid or pasty products, free-flowing-powder or granulates and non-free-flowing fine powders. Bag shape can be customized for various attractive shapes.