N95 Respirator Mask / Facemask Production & Packaging Lines

Turnkey Solution for N95 Respirator Mask / Facemask Production & Packaging Lines for USA & Canada

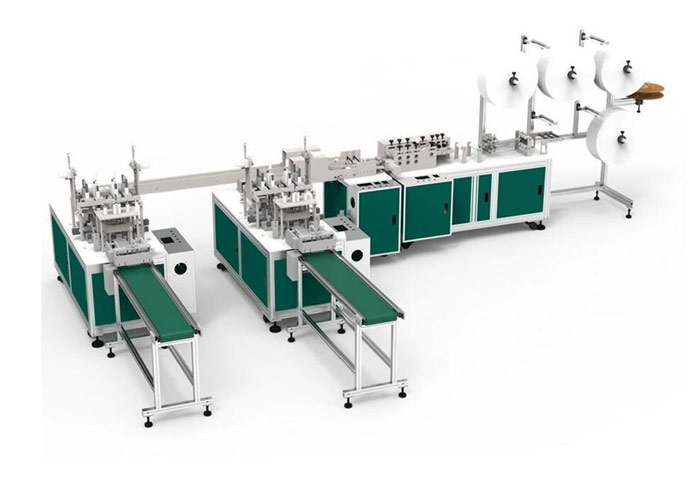

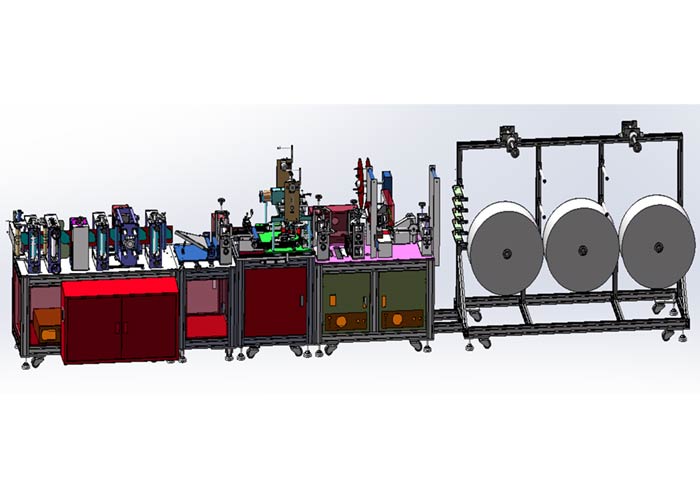

LENIS MACHINES offers turnkey solutions for N95 Respirator Mask or Facemask Production & Packaging Line of Machines including all the raw materials required to make high-quality facemasks. These highly sophisticated & state of the art machines make about 30 ~ 40 pcs N95 respirator masks per minute. We also offer a full packaging line including a Delta-Robot Vision-based Pre-Packing Sorting/Aligning Machine, Flow Wrapping/Shrink Wrapping Machine, Boxing Machine, Carton Erector, and Carton Sealing Machine as a comprehensive line of mask production and packaging. These machines contain high-quality electrical components for ruggedness and reliability including all SIEMENS PLC, Motion Controller, Servo Motors & Servo Drives.

These machines are mainly for the North American market. The machines will be commissioned and tested at our Vancouver, Canada warehouse for certification of the machines if required by the client (for Canada it is a mandatory step) and will provide training on the full production and packaging process and then repack and ship the whole line to the client in an easy, modular, and well-documented manner. We will provide post-sale-support from our Vancouver office.

Mask Production Line Configuration

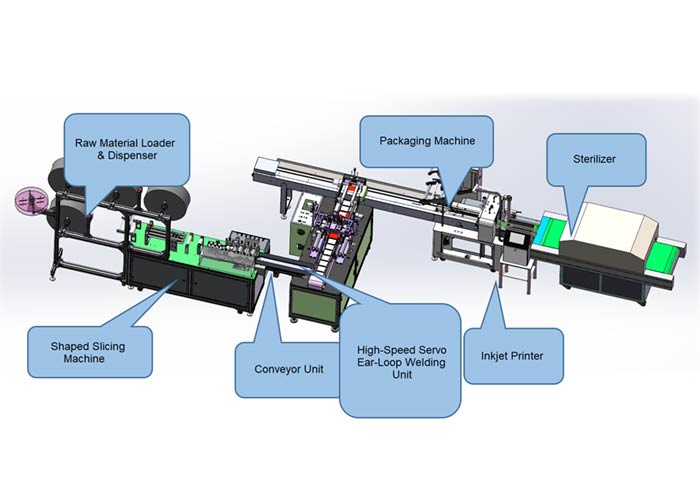

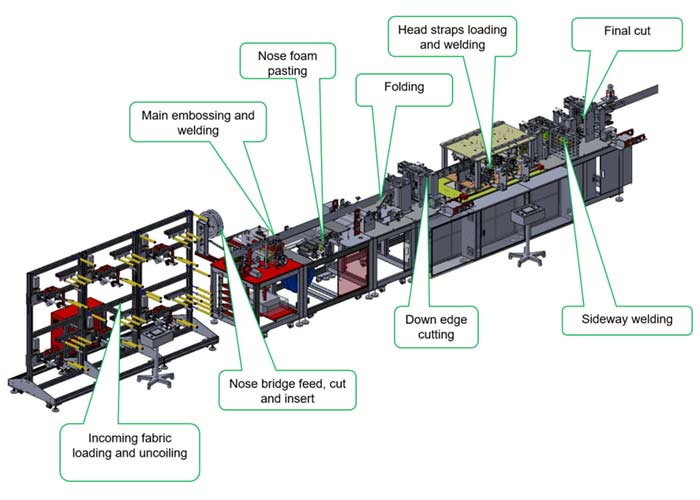

- Fully Automatic N95 Head-Band, Nose-Clip & Nose Foam Based Respirator Mask or Facemask Production Machine

- Fabric coil payoff device – servo driven

- Nose clip payoff device – servo driven

- Nose clip cutting device – air cylinder driven

- Nose clip feeding device – servo driven

- Fabric embossing, welding device – servo driven

- Printer – HP Inkjet

- Nose foam pasting – servo driven

- Fabric mechanical folding device

- Downside edge cutting and scrap fabric collection device – servo driven

- Headwear loop welding device – speed synchronous movement driven by servo motors

- Fabric side edge sealing device – speed synchronous movement driven by servo motor

- Upper edge rotating cutter device – servo driven

- Finished product output device

- Scrap fabric collection device

- Control system

- Control panel

Optional Mask Packaging Line Configuration

- Vision-Based Delta-Robot Mask Sorter Machine for Perfect Pre-Packaging Alignment of the Masks

- Flow Wrapper or Shrink Wrapper Machine depending on client’s requirement

- Mask Boxing Machine

- Carton Erector

- Carton Filling Machine

- Carton Folding and Sealing Machine

Mask Features

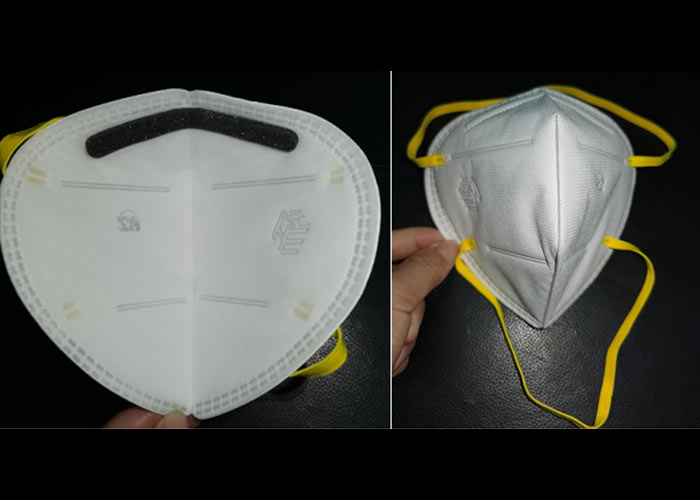

- Headband based N95 respirator masks

- Nose clip and nose foam in the mask

- The foldable design of the mask makes it

- Mask quality and specification passes NIOSH N95 mask criteria when used with proper fabrics

Standards

- Standard Machine with CE Certification

- Optional certification in Accordance with CSA directives for Canadian clients (must for Canadian clients)

- Optional certification through OSHA accredited NRTL for The USA clients

Machine Features

- The machine is based on welded steel structure which is rigid and very strong, unlike the aluminum-framed machines. Adopts think 7075 aluminum plate material which is light but very strong and rust-resistant for the machine body. Each part of the machine is fixed on the solid plate part of the machine body and fixed with a pin and screw making the machine very stable and causing low vibration while running which increases the quality of the end product and enhances machine life.

- The unwinder unit is driven by servo motors. There are six servo motors to operate six main spindles. The uncoiling speed is synchronized to be exactly the same as the main machine making fabric uncoiling fabric at a uniform tension very smoothly.

- Each action of the line e.g. embossing, nose bridge insertion, nose bridge cutting, ear-loop welding, side-sealing, and final cutting, all are controlled by separate high-performance servo motors. The synchronous working of all the motions of the machine is controlled by a high-end Siemens motion controller. This technology is called Electronic Camming, a highly accurate and advanced alternative of mechanical cam technology that is used in traditional mask machines where each servo motor runs according to the electronic cam settings. It’s very stable and accurate and not prone to a cumulative measurement error which occurs in mechanical cam-based machine designs which needs periodic re-tuning while in production causing precious production delays and expensive man-hours. The electronic cam is easy to operate and auto-compensates and auto-tunes for cumulative errors.

- This N95 mask line runs in synchronized mode by running all the processes at the same linear speed keeping the same tension to the fabric all the way making high quality and finish of the produced N95 respirator masks. The ultrasonic welders work in continuous mode as well without any intermittent start and stop operation which makes the welding quality very consistent and stable.

- The servo-drive system holds the fabric in uniform tension while the machine is in a “Standby” state (not power-off condition). So the tension in the fabric still remains intact when the operation shift changes and the new operation shift starts after a break. This eliminates machine re-adjustments which saves time and money and easy for the machine operator taking over the machine for the next work-shift.

- This machine is equipped with remote diagnostics & troubleshooting capability and the machine settings can be adjusted by the manufacturer remotely or can be diagnosed for error in operation for remote troubleshooting, training, and maintenance.

| Parameters | Specifications |

|---|---|

| Productivity | 30 ~ 40 masks/min |

| Use Environment | Temperature 10~35℃, Humidity of 5-35%HR, non-corrosive gas and non-dusty |

| Compressed Air Consumption | 0.6 ~ 0.8 MPa, 300L/min |

| Power & Supply Voltage | 18kW, 208V/600V AC3P, 50/60Hz |

| Machine Dimensions (L x W x H) | 9200mm x 1760mm x 1920mm |

| Machine Weight | 3000 kg |

| Parameter Group | Parameters | LMDDS-280 | LMDDSZ-280 | LMDDSC-280 |

|---|---|---|---|---|

| Packaging Parameters | Pouch Type | Doy Pack, Flat Pouch | Doy Pack, Flat Pouch with Zipper | Pouch with Spout |

| Packaging Parameters | Packing Material | Laminated Film | Laminated Film | Laminated Film |

| Packaging Parameters | Min Pouch Size | 90 mm x 110 mm | 90 mm x 110 mm | 90 mm x 110 mm |

| Packaging Parameters | Max Pouch Size | 140 mm x 250 mm | 140 mm x 250 mm | 140 mm x 250 mm |

| Packaging Parameters | Max Volume | 600 ml | 600 ml | 600 ml |

| Packaging Parameters | Max Packing Speed | 90 ~ 120 bags/min | 90 ~ 120 bags/min | 90 ~ 120 bags/min |

| Packaging Parameters | Number of Filling Stations | 2 | 2 | 2 |

| Machine Function | Standard | Date Printing, Output Conveyor | Date Printing, Output Conveyor | Date Printing, Output Conveyor |

| Machine Function | Optional | No-bag-no-fill, Ascetic Packing, Anti-static, CIP, Anti-Drooping Filling | No-bag-no-fill, Ascetic Packing, Anti-static, CIP, Anti-Drooping Filling | No-bag-no-fill, Ascetic Packing, Anti-static, CIP, Anti-Drooping Filling |

| Working Conditions | Power Consumption | 13.5 kW | 15.5 kW | 15.5 kW |

| Working Conditions | Air Consumption | 400 NL/min | 400 NL/min | 400 NL/min |

| Working Conditions | Ambient Temperature | -10C ~ 55 C | -10C ~ 55 C | -10C ~ 55 C |

| Working Conditions | Relative Humidity | Below 85% (Non Condensation) | Below 85% (Non Condensation) | Below 85% (Non Condensation) |

| Working Conditions | Supply Voltage | 208V AC, 3 Ph, 60 Hz (or Custom) | 208V AC, 3 Ph, 60 Hz (or Custom) | 208V AC, 3 Ph, 60 Hz (or Custom) |

| Dimensions & Weight | Dimensions (L x W x W) | 9220 mm x 1210 mm x 1500 mm | 10120 mm x 1210 mm x 1500 mm | 10120 mm x 1210 mm x 1500 mm |

| Dimensions & Weight | Weight | 3000 kg | 3200 kg | 3200 kg |