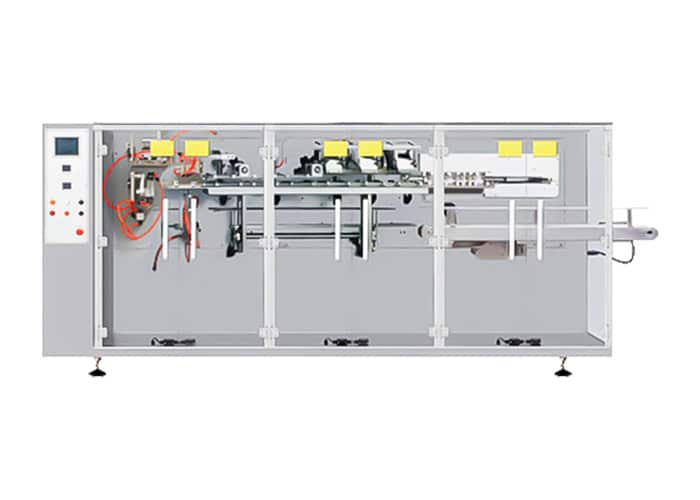

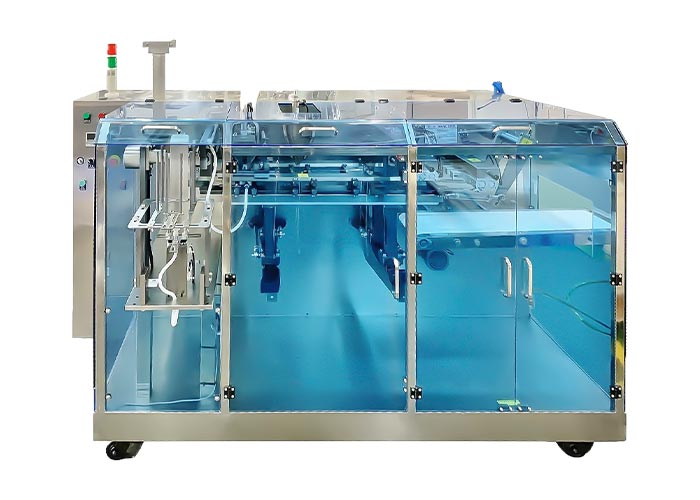

LMHDP5 Horizontal Premade Doypack / Flatpack Pouch Packaging Machines

The LMHDP5 Horizontal Premade Doypack Standup & Flatpack Pouch Packaging Machines provide economical medium speed solutions for packaging modern premade Doypack standup pouch and flatpack pouch packing. This compact horizontal premade pouch packaging machine provides a stable solution for packing powder, granular products, liquid, and pasty products for small to medium-sized production units.

LENIS provide GMP Documentation Package (IQ/OQ/PQ) as an option for all the supplied equipment.

LENIS also provides NRTL based machine certification option for US customers and mandatory machine certification in accordance with CSA directives for Canadian customers. Most of our machines come with CE certification as a standard.

Machine Features

- SS304 Steel Machine Frame

- The simple design of empty bag detection & collection with automatic bags pressing device.

- Pressure sensor device to detect empty bags or missed bags and no materials filling and sealing keeps machine clean in case of bag loading fault

Bag Types

These machines can work with pre-made bags of the following types:

- Standup pouches or Doypack pouches with or without zippers

- 3-side sealed pouches with or without zippers

- 4-side sealed pouches with or without zippers

Filler Options

- Auger Filler (for powder products)

- Volumetric Cup Filler (for grains)

- Multi-head Weigher (for grains and granular items like chips, candies, etc.)

- Piston Pump (for liquid products)

- Tablet Counting Filler (for tablets)

- Vibrating Fillers (for block items, nails, screws, etc.)

Machine Options

- Bag tapper

- Hopper shaker

- No drip tray

- Vacuum suction function

- Gas flush functions

- Date code printer, etc. are among many options available

Build Material Options

- SS304 stainless steel based product contact parts for general food/cosmetics/pharmaceutical industries

- SS316 corrosion-resistant stainless steel-based product contact parts for highly corrosive products like salt, chemicals, etc.

Optional Related Equipment

- Screw elevator/conveyor for automatic continuous feeding of powder products

- Z-bucket elevator for automatic continuous feeding of granular products

- Agitator/mixer for liquid or paste products

- Product counter and stacking belt conveyor

- Extra filler equipment for different powder, granular, liquid, or part type products packaging in a single machine. The choices are: volumetric cup filler, 2-head/4-head linear weigher, piston pump filler, auger filler, tablet counting filler, and vibrating filler

- Air compressor

- Possibility of machine integration with ERP system. (SAP, Microsoft Dynamics, and other ERP software)

- SCADA integration

- Complete production line including Metal Detector, Boxing Machines, Wrapping Machines, etc.

Standards

- In accordance with CE Standards

- Optional accordance with OSHA accredited NRTL Certification for USA and CSA for Canada

| Parameters | LMHDP5-160 | LMHDP5-210 | LMHDP5-260 |

|---|---|---|---|

| No of Stations | 5 stations | 5 stations | 5 stations |

| Bag Size (L x W) | (10 ~ 230)mm x (90 ~ 160)mm | (110 ~ 280)mm x (110 ~ 210)mm | (120 ~ 380)mm x (120 ~ 260)mm |

| Packing Speed | 5 ~ 50 bags/min | 5 ~ 50 bags/min | 20 ~ 50 bags/min |

| Air Consumption | 0.7 m3/min | 0.7 m3/min | 0.7 m3/min |

| Power & Supply Voltage | 2kW, 220V, 50/60Hz | 2kW, 220V, 50/60Hz | 7.5kW, 220V, 50/60Hz |

| Dimensions (L x W x H) | 1750mm x 1285mm x 1360mm | 2140mm x 1366mm x 1360mm | 2430mm x 1400mm x 1360mm |

| Machine Weight | 800 kg | 900 kg | 1000 kg |