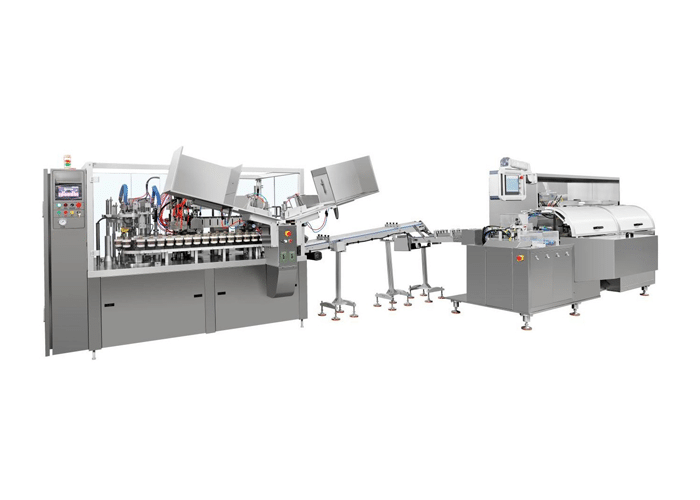

CapPACKER Bottle Packer- Complete Automatic Capsule/Tablet/Gummy Counting, Filling, Capping, Labeling & Cartoning Line

Description

Features

Specifications

Videos

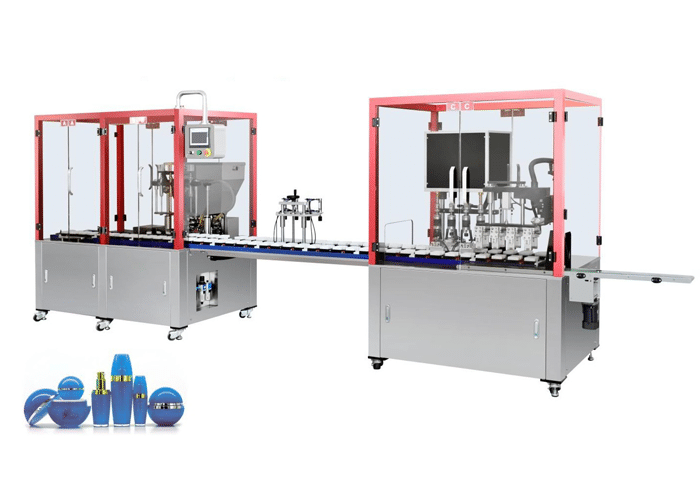

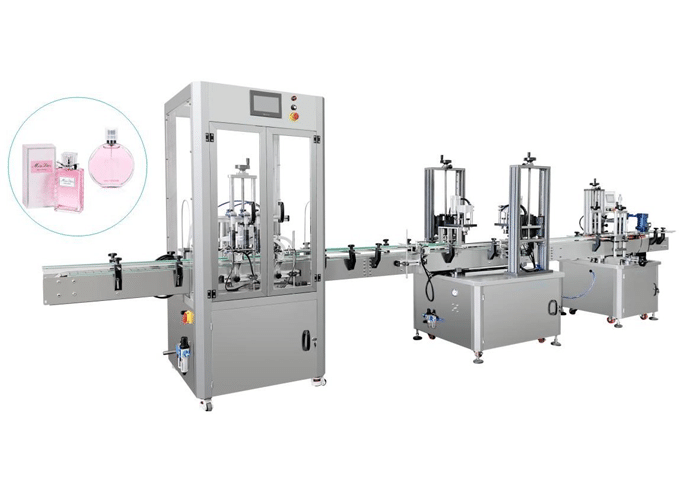

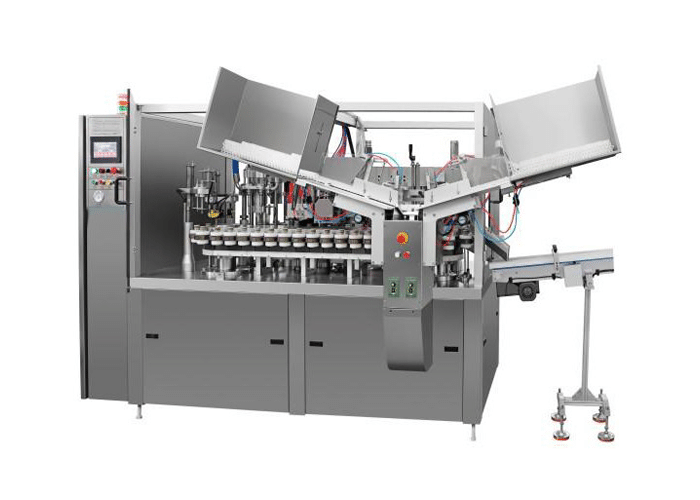

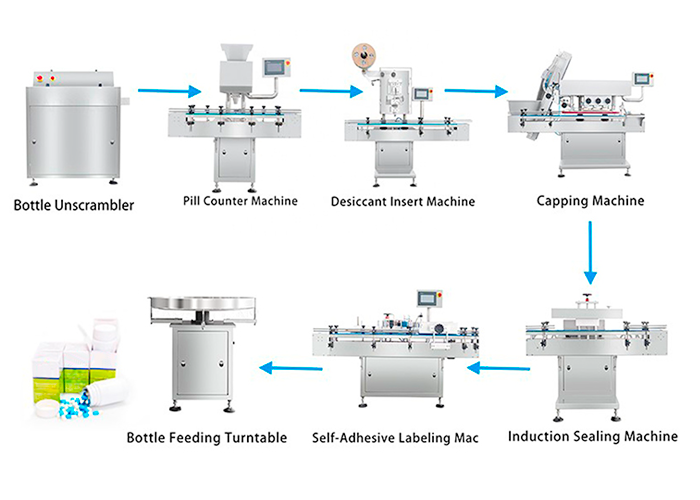

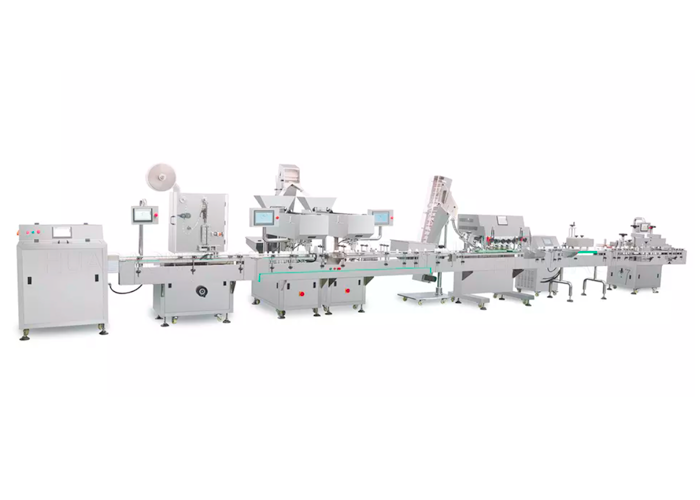

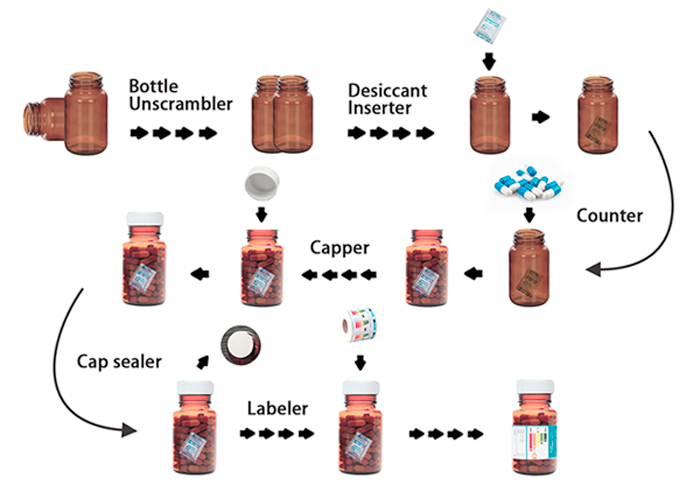

The CapPACKER is an automatic bottle packing line for tablets, capsules or gummies. The packaging line may contain the following according to the process requirement:

- Turntable or Bottle Unscrambler

- Bottle Air Cleaning Machine

- Desiccant Dispenser

- Capsule/Tablet Counter

- Cotton Dispenser

- Automatic Cap Feeder

- Automatic Capping Machine

- Induction Sealing Machine

- Sleeve Insertion & Shrinking Machine

- Labelling Machine

- Rotary Collection Table

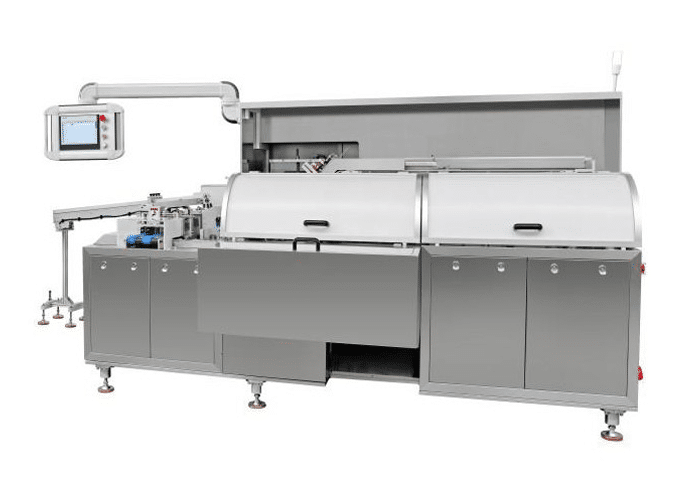

- Automatic Cartoning Machine

- Overwrapping Machine

Features

- Suitable for counting and filling tablets, capsules and gummies in bottles

- Bottle unscrambler is used for loading and oriented supply of round/square plastic containers to the automatic line at a maximum speed of 120 bottles/min depending on the bottle size.

- Desiccant insertion machine for inserting desiccant sachets to each bottle.

- Standard 8 lane in one channel or 16 lanes in 2 channel capsule/tablet/gummy/soft gel capsule counter

- High-speed capping machine with automatic cap inserter applicable for different sizes of round, square bottles and containers with different types of caps including CRC cap.

- High-speed induction sealer capable of sealing 200 bottles/min and handling different sizes of round, rectangular and irregular shaped bottles and containers.

- Includes a self-adhesive labeling machine for round bottle or square shaped bottles depending on the process.

- An automatic sleeve inserter and shrinking machine can be included in the line for additional sealing of the cap.

- Line may include a rotary collection table for collecting the final product or may convey the finished bottles for cartoning and overwrapping application.

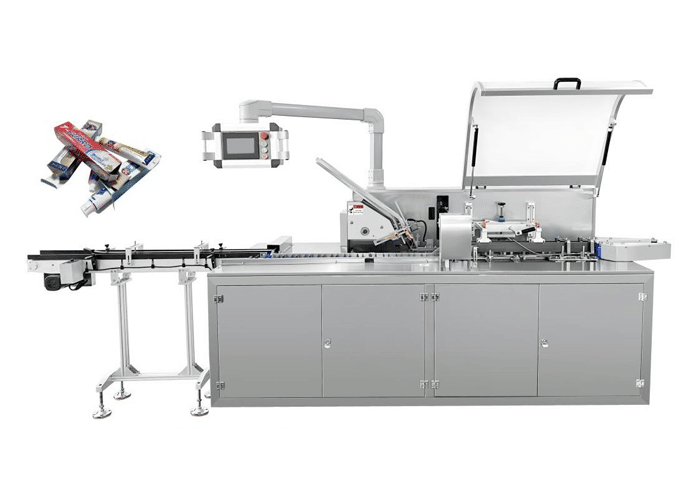

- A cartoner machine can be added for secondary packaging of the bottles into a paper carton. The cartoner is an automatic machine for grabbing, unfolding, filling and closing of paper cartons for secondary packaging.

- Some bottle packaging line may include an overwrapping machine after the cartoner for cellophane wrapping of the cartons.

Standards

- In accordance with CE Standards

- Optional accordance with OSHA accredited NRTL Certification for USA and CSA for Canada

This line can be customized to accommodate a wide range of bottles and jars for capsule/tablet/gummy packing application. Contact us with your detailed requirements.