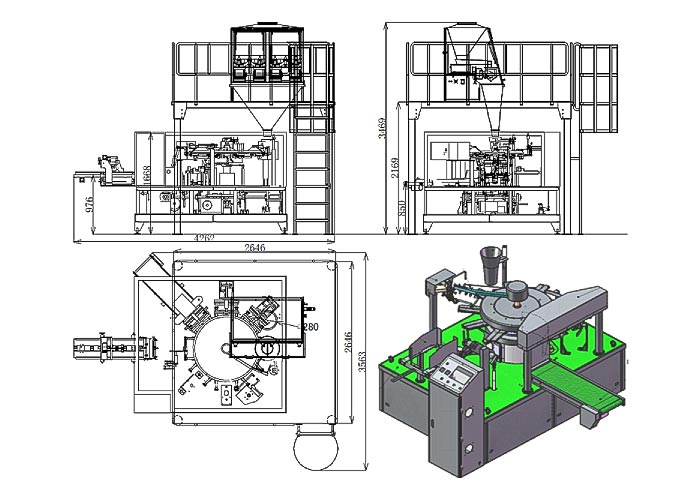

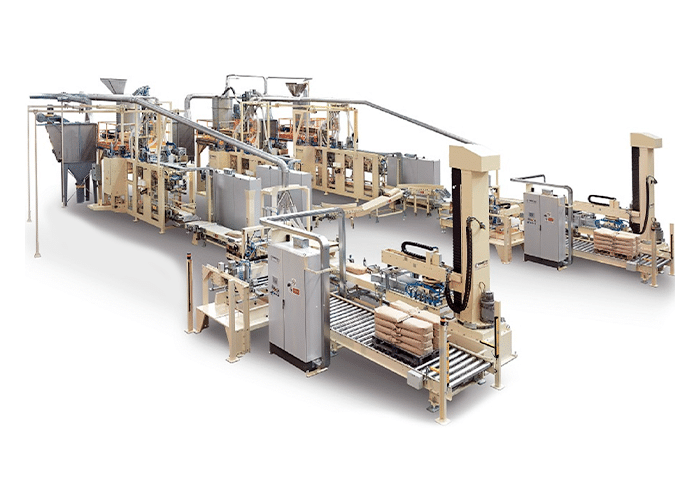

Customized & Specialized Machinery Solutions

Do you have a challenging project with a need for customized or specialized machinery? No off-the-shelf machines are good enough for your special project? You are at the right place then!

We love challenging, customized & specialized projects which others are reluctant to take. We design and build customized and specialized machinery and can offer you a total turnkey solution for a complete and complex line of customized machines. Contact us with details of your requirement. Give us a call or send us a detailed email and let us discuss and plan a solution to your specialized problem in hand. We are confident that we can offer you the best solution at a competitive price-point.

Contact us with details of your requirement. Give us a call or send us a detailed email and let us discuss and plan a solution to your specialized problem in hand.

Contact us with details of your requirement. Give us a call or send us a detailed email and let us discuss and plan a solution to your specialized problem in hand.