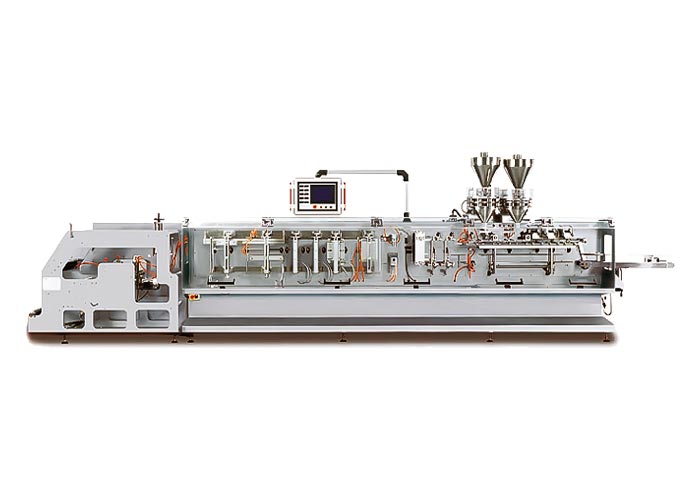

MUSTANG-180 Horizontal Form, Fill & Seal (HFFS) Doypack, Spout Pack, Flatpack Pouch Packaging Machines

The MUSTANG-180 Horizontal Form, Fill & Seal (HFFS) Packaging Machines make, fill, and seal pouches in one automatic process. These high-performance machines eliminate the need for pre-made bags by using laminated roll stock film to create a large variety of pouch styles and reduce material cost dramatically. As opposed to purchasing pre-made pouches, cost savings of up to 30% may be incurred by producing a finished product in these machines.

The MUSTANG-180 makes, fills & seals Doypaks, Doypack with zippers, larger Flatpacks, mold-cut shaped standup pouched, and standup spout pouches for liquids. This high performer delivers pouches of premium quality of seals and appearance.

LENIS provide GMP Documentation Package (IQ/OQ/PQ) as an option for all the supplied equipment.

LENIS also provides NRTL based machine certification option for US customers and mandatory machine certification in accordance with CSA directives for Canadian customers. Most of our machines come with CE certification as a standard.

Bag Types

The servo-driven HFSS machines can produce 3-side seal pouches and 4-sided seal flatpack pouches or flat packs, Doypack standup pouches, mold-cut shaped Doypacks, and standup spout pouches for liquid packing.

Fully Automatic Bag Forming

These high-performance machines eliminate the need for pre-made bags by using laminated roll stock film to create a large variety of pouch styles and reduce material cost dramatically. As opposed to purchasing pre-made pouches, cost savings of up to 30% may be incurred by producing a finished product in these machines.

Filler Options

- Auger Filler (for powder products)

- Volumetric Cup Filler (for grains)

- Multi-head Weigher (for grains and granular items like chips, candies, etc.)

- Piston Pump (for liquid products)

- Tablet Counting Filler (for tablets)

- Vibrating Fillers (for block items, nails, screws, etc.)

Machine Options

- Hole punch device

- Gas flush device

- Middle capping device

- The shaped bag molding device

- Stand-up pouch former

- Tear notch device

- Zipper application device

- Vacuum station etc. are among many options available

Build Material Options

- SS304 stainless steel based product contact parts for general food/cosmetics/pharmaceutical industries

- SS316 corrosion-resistant stainless steel-based product contact parts for highly corrosive products like salt, chemicals, etc.

Optional Equipment

- Possibility of machine integration with ERP system. (SAP, Microsoft Dynamics, and other ERP software)

- SCADA integration

- Screw elevator/conveyor for automatic continuous feeding of powder products

- Z-bucket elevator for automatic continuous feeding of granular products

- Agitator/mixer for liquid or paste products

- Product counter and stacking belt conveyor

- Extra filler equipment for different powder, granular, liquid, or part type products packaging in a single machine. The choices are: volumetric cup filler, multi-head weigher, piston pump filler, auger filler, tablet counting filler, and vibrating filler

- Air compressor

- Complete line including Metal Detector, Check Weigher, Boxing or Cartoning Machine, Robot Palletizer, Pallet Wrapping Machines, etc.

Standards

- Accordance with CE Standards

- Optional accordance with OSHA accredited NRTL Certification for USA and CSA for Canada

| Parameters | MUSTANG-180S | MUSTANG-180SZ | MUSTANG-180SC |

|---|---|---|---|

| Pouch Type | Doypack, Shaped, Hanging Hole (zipperless) | Doypack, Shaped with Zipper | Doypack, Shaped, Spout Pack |

| Packing Material | All kinds of laminated films | All kinds of laminated films | All kinds of laminated films |

| Min Pouch Size | 90 mm x 110 mm | 90 mm x 110 mm | 90 mm x 110 mm |

| Max Pouch Size | 180 mm x 250 mm | 180 mm x 250 mm | 180 mm x 250 mm |

| Max Volume | 1000 ml | 1000 ml | 1000 ml |

| Max Packing Speed | 40 ~ 60 bags/min | 40 ~ 60 bags/min | 40 ~ 60 bags/min |

| Number of Filling Stations | 2 | 2 | 2 |

| Standard Functions | Date Printing, Output Conveyor | Date Printing, Output Conveyor | Date Printing, Output Conveyor |

| Optional Functions | No-bag-no-fill, Ascetic Packing, Anti-static, CIP, Anti-Drooping Filling | No-bag-no-fill, Ascetic Packing, Anti-static, CIP, Anti-Drooping Filling | No-bag-no-fill, Ascetic Packing, Anti-static, CIP, Anti-Drooping Filling |

| Air Consumption | 300 NL/min | 300 NL/min | 300 NL/min |

| Ambient Temperature | -10℃ ~ 55℃ | -10℃ ~ 55℃ | -10℃ ~ 55℃ |

| Relative Humidity | Below 85% (Non Condensation) | Below 85% (Non Condensation) | Below 85% (Non Condensation) |

| Power Consumption | 8 kW | 8 kW | 8 kW |

| Supply Voltage | 220V, 3 Phase, 50/60Hz | 220V, 3 Phase, 50/60Hz | 220V, 3 Phase, 50/60Hz |

| Dimensions (L x W x W) | 6000 mm x 1100 mm x 1500 mm | 6000 mm x 1100 mm x 1500 mm | 6000 mm x 1100 mm x 1500 mm |

| Weight | 2000 kg | 2000 kg | 2000 kg |

LENIS MUSTANG Series Horizontal Form, Fill & Seal HFFS Machines

LENIS MUSTANG Series Horizontal Form, Fill & Seal or HFFS Doypack Standup Pouch Packaging Machines are the workhorses of modern pouch packaging industries. LENIS offers fully customized and high-performance MUSTANG Series HFFS machines that are economical in the long run as those make the pouch in the machine itself from a roll of film. High quality control system based on Siemens PLC and HMI offers ruggedness and unbeatable reliability in control and operation. We also offer spout packs for liquids, and flat pack HFFS machines for varieties of industries.