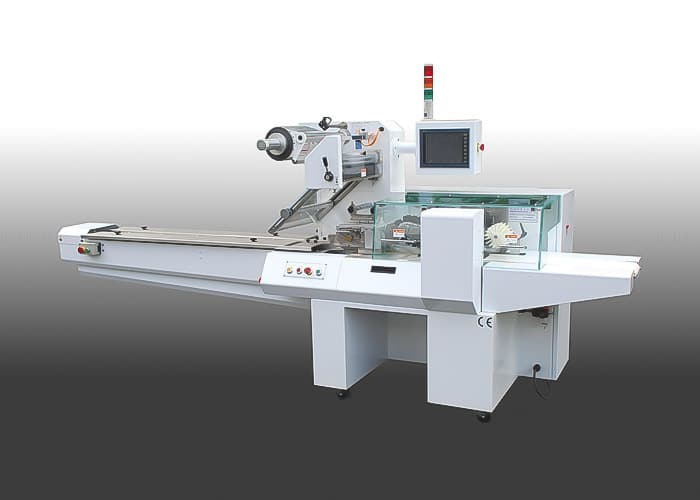

METEOR Servo Wrappers, Horizontal Flow Wrapping Packaging Machines

The METEOR Servo Wrappers are economical flow wrappers with 3-servo based motion control for high accuracy and smooth operation. These wrappers can pack a variety of foods and other industrial products, meet productivity goals easily and reduce production cost streamlining your production and packaging needs. These standard horizontal flow wrapping machines adopt Rotary Motion Sealing technology for high-speed running and cost-effective packaging operation. The METEOR Servo wrappers pack products from a film in a roll and form a three-side sealed pillow pack or a gusset bag. These machines can be customized with different levels of control in operation and various kinds of accessories for different application requirements and come in various sizes to suit your specific application.

Machine Features

- Powder coating machine frame for durability

- 3 – servo motor based drive system makes the machine run precisely and smoothly

- The PLC-based control system ensures reliable and safe operation

- Color Touch Panel HMI

- Running speed, bag length, mark position, could be memorized and can be changed easily & quickly to meet production specification

- Eye-mark Registration

- Protection devise on the in-feed conveyor and easy to reset

- “No-fill no-pack” function saves packaging material when the operator misses filling product on the conveyor

Optional Accessories

- Date coder

- End-seal gusset

- In-feed carrier block

- Auto labeling device

- Additional reel holder

- Transfer belt

- Auto feeding system

- Gas flushing device

- End-seal euroslot punch

- Transfer chain conveyor

Packaging Applications

- Bakery

- Biscuits & Snacks

- Candy & Confectionery

- Refrigerated & Frozen Food

- Fresh Food

- Shrink Packaging

- Wet Wipes / Tissue

- Printing Items

- Detergents

- Pharmaceutical & Medical

- Hardware & Tool

- Instant Noodles

- Miscellaneous

Standards

- Accordance with CE Standards

- Optional accordance with OSHA accredited NRTL Certification for USA and CSA for Canada

| Parameters | METEOR-110E |

|---|---|

| Packaging Speed | 50 to 300 bags/min |

| Max Film Width | 76mm ~ 210mm |

| Bag Length | 100mm ~ 300mm |

| Bag Width | 30mm ~ 110mm |

| Bag Types | Pillow bag, gusseted bag |

| Max. Product Height | 35mm / 55 mm |

| Max Film Roll Diameter | 380 mm |

| Power & Supply Voltage | 2.6kW, 220 Volt, 50/60Hz |

| Film Material | OPP, PE, PVC, OPP/CPP, PT/PE, KOP/CPP etc. |

| Dimensions (L x W x H) | 3600 mm x 670 mm x 1470 mm |

| Machine Weight | 400 kg |